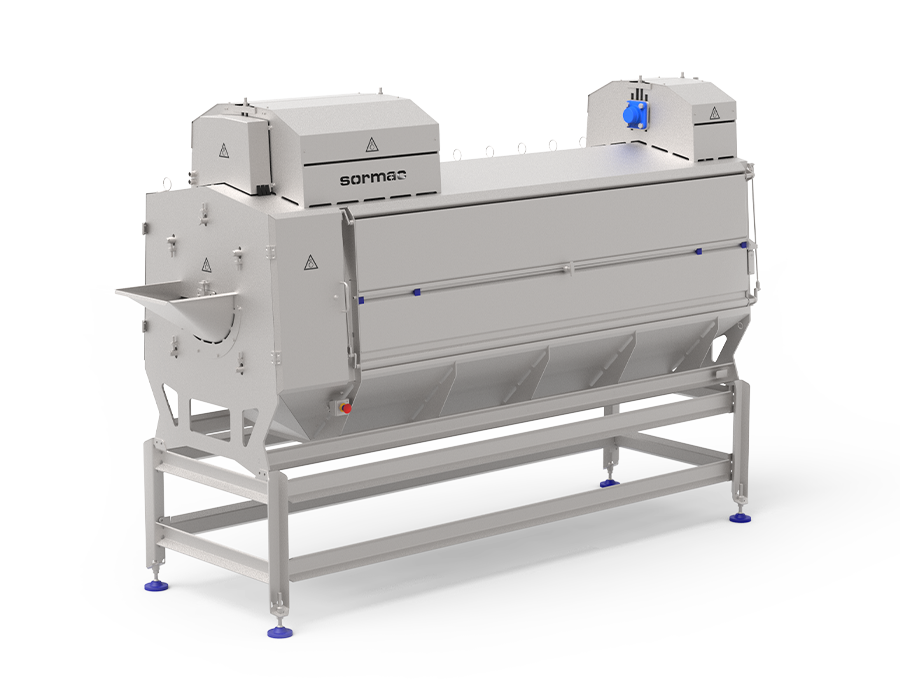

Revolver peeler CRR

A revolver peeler with a number of peeling rollers which form an elongated drum. This is especially suitable for small products like e.g. baby carrots.

Machine name

Revolver peeler

Model number

CRR

Dimensions

4,030 x 1,270 x 2,585 mm

Products

Applications

Peeling & polishing

Capacity

Capacity depends on product

Product specifications

Ø5 - 45 mm, max. length 200 mm

Features

The power of innovation

Our engineers are always working on the machines of tomorrow. Each and every day they look for the smallest details that will make a difference. We set the trends and new standards in the vegetable processing industry.

Easy to clean

The machine’s drum is equipped with a folding roller, which makes it easy to clean the inside of the drum, especially the conveyor screw.

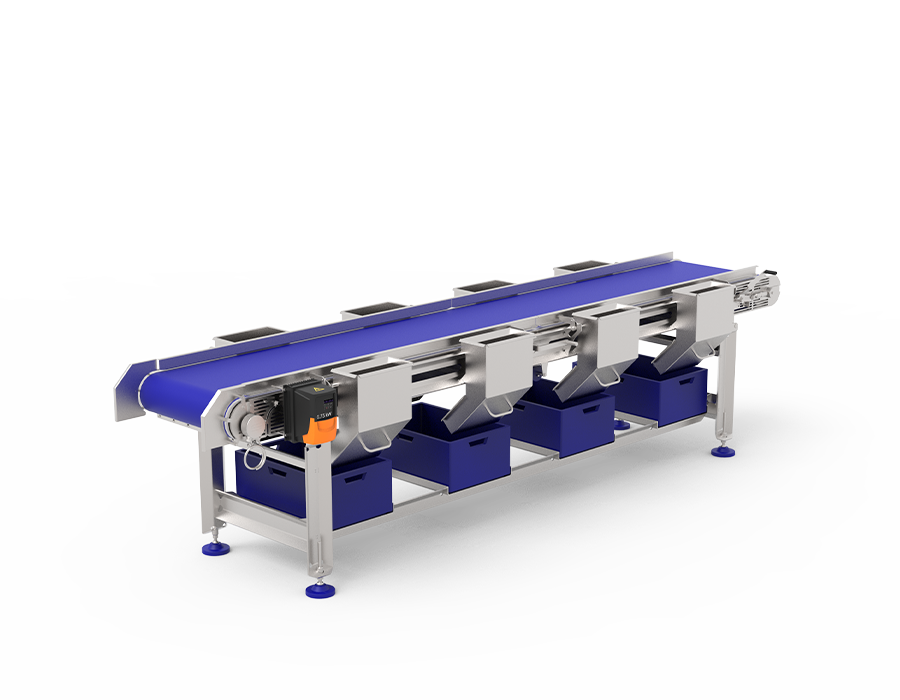

Positioned in processing line

Baby carrot line

Producing baby carrots requires specialised machines for the various stages of the production process. These are: cutting, grading, peeling, polishing and cooling.

Contact us

Do you have a question, or wish to make an appointment?

Do you have questions about a machine, process, or challenge? Please fill out the contact form below. We’ll contact you promptly.

We can help you with...

- Identifying the best machine for your specific needs

- Integrated processing lines of our proven machines

- Custom total solutions and full project management

Prefer to call? Ring us on +44 (0) 1284 530 700 (Mon-Fri, 08:00 - 17:00 h)

Who are we

About Sormac

As the leading specialist in the development and manufacturing of machinery for the vegetable processing industry, Sormac prides itself on being a family business renowned for it's reliability, quality, and knowledge.

- Everything in-house: development, engineering, manufacturing

- Own microbiological laboratory

- Innovative solutions for your entire process